-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How to Specify

- How to Install

- How to Maintain

- Projects

- Contact

Tūhoe Living Building - Lake Waikaremoana, New Zealand

Tūhoe have now completed their second Living Building project, which also uses Abodo’s FSC® certified, sustainably harvested eco-timbers

Project details

- Architect

- Tennent and Brown

- Product

- Vulcan Cladding

- Sand Decking in Protector - Pearl

- Completion date

- Late 2016

- Location

- Lake Waikaremoana, New Zealand

This is not the first time Tūhoe have taken on a Living Building Challenge.

Their award-winning Te Kura Whare was the first Living Building in New Zealand and the Iwi have now completed their second Living Building project, which also uses Abodo’s FSC® certified, sustainably harvested eco-timbers.

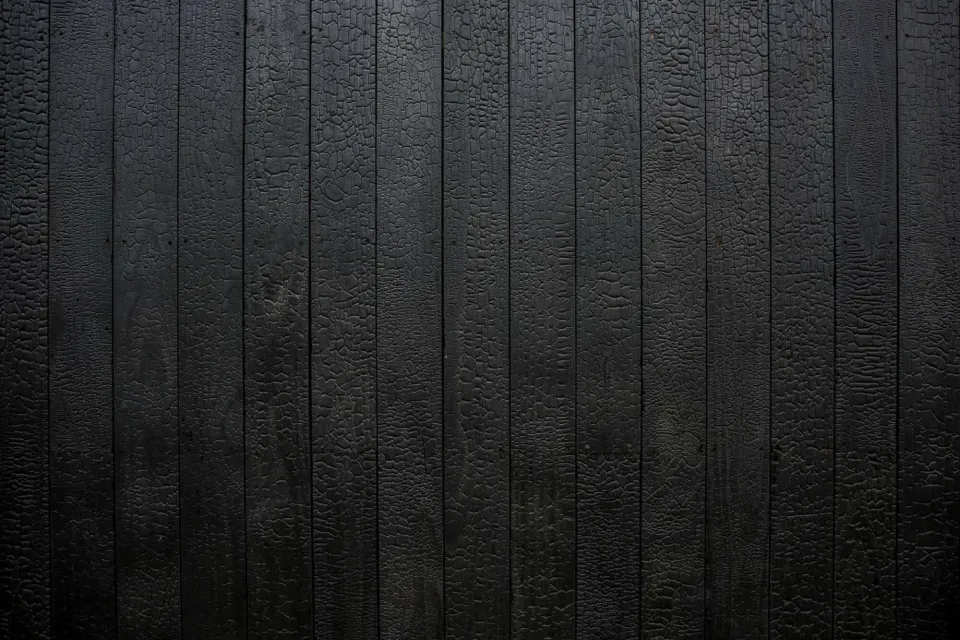

The Visitor’s Centre features charred Vulcan Cladding on the façade, with two large panels at either end of the building. The charred timber panels are symbolic of an important event in the tribe’s history, when the Crown employed its scorched earth policy against Tūhoe in 1867.

The panels were created onsite by Iwi and Abodo staff members, using a traditional Japanese method of preserving wood (‘Shou Sugi Ban’) by burning the surface of the timber to a consistent depth of char.

After charring, the boards were sealed with Protector - Ebony, to prevent rub off. Charred timber, if produced correctly can last for generations.

Vulcan timber was also used for window and door joinery (finished with Protector), the Centre's decks are in Sand Decking, finished in Protector - Pearl.

Where feasible, the building also uses locally sourced materials and labour.

Importantly for Ngai Tūhoe, where the meaning behind the wood also plays its part, the wood fibre used for the project is locally sourced by Abodo from FSC® certified forests in the Kaingaroa region, most of which are on or close to Ngai Tūhoe land.

The Visitor’s Centre includes ticketing (for the great walk), café and kitchen, administration, retail and a wānanga space.

The building is reflective of the lake and the surrounding geomorphology, designed by the talented architects at Tennent Brown.

We’re proud to work with Tūhoe on their second Living Building challenge, supplying Abodo sustainably harvested, eco-timber joinery and cladding.

The Centre opened on 23 December 2016.

Awards:

- Commercial Architectural Excellence Award

- Wood & Fibre Creativity Award

Products

See more about the products that have been used on this project.